| 震动 | 无 |

|---|---|

| 系统精度 | 0.01 |

| 温度量程 | -40℃~200℃ |

| 环境温度 | -20℃~54℃ |

| 环境等级 | 0 |

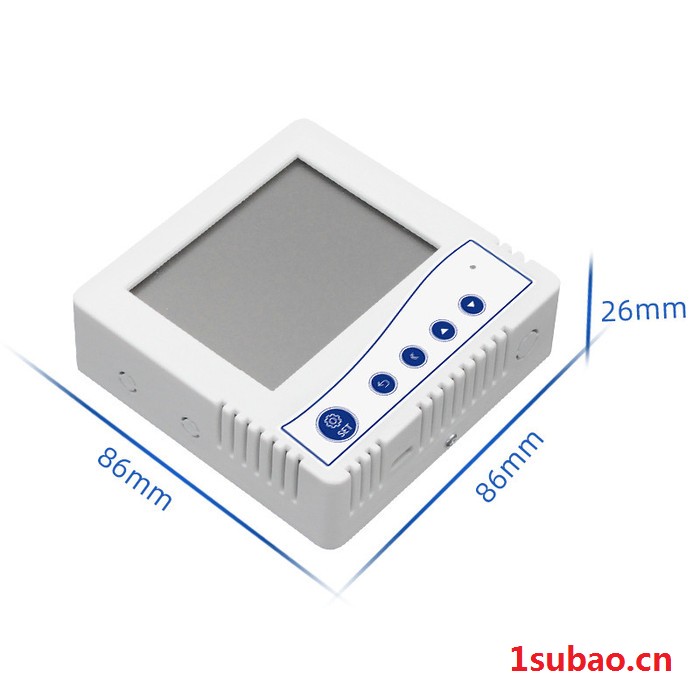

| 规格 | 34.3×18.4×11.4 cm |

| 分度值 | 0.01 |

| 电路盒 | 5A |

| 测量范围 | -40℃~200℃ |

| 测量精度 | 0.1 |

| 产地 | 美国 |

| 类型 | 隔爆式双金属温度计 |

| 适用范围 | 石化 |

| 外形尺寸 | 30*15*15 |

| 显示方式 | 数显式 |

| 品牌 | Thermoprobe |

| 型号 | TP7 TP7C |

| 加工定制 | 否 |

TP7防爆安全温度计(THERMO)

TP7采用RTD设计,密封覆盖的工业质量给用 户提供了一个容易用手套操作的界面。不锈钢外 壳保护电路板和液晶屏,防止遭受水等液体渗透 的影响。

TP7电路板是从高度**、可靠及 成功的TL1实验室温度计一步步演变而来。电源 按钮的主要功能是提供仪器上次按触后约20分钟 的电量, 为了忍受环境以及内在的安全,制造TP9的 材料都是既能防止石化产品的腐蚀,又能够防 爆。外壳由不锈钢制成。探头的构造使用不粘电 缆和不锈钢传感器组件。

· **大尺寸:34.3×18.4×11.4 cm Ÿ

· 总重量:配有23m电缆的质量为1.4千克Ÿ

· 电池类型:9V碱性电池

· 电池寿命:约50小时

· 电池工作温度范围:-20℃~54℃(注:当环境温度高于54℃或低于4℃,电池将不能充分供电) Ÿ

· 表壳材质:聚丙烯共混材料,不锈钢和铝Ÿ

· 保质期:探头90天,其它元件1年Ÿ

· 内置铂电阻的不锈钢传感器外有防静电电缆套管,芳纶纤维加强了抗切割和耐碎性。Ÿ

· 电缆采用碳氟化合物,如FEP、PFA或相似材料作为绝缘材料Ÿ

· 温度:温度范围:-10℃~188℃(14℉~370℉),分辨率:0.1℃,校正后精度:32℉~200℉±0.2℉;200℉~300℉±0.5℉,0℃~100℃±0.1℃;100℃~150℃±0.3℃,长期**度漂移不超过 0.05%/年Ÿ

· 符合API要求

· 安全等级:II 2 (1) EEx ib[ia] IIB T4

操作属性

易于更换的AA电池,提供的估计200小时运行。

逻辑电路会自动显示电池电量不足时,自动关机二十分钟后,显示温度趋势和稳定,故障确定显示的错误代码。

低功耗背光,方便夜间操作是为了方便和节约电池的光电传感器控制。

在夜间条件下的背光照明显示。

摄氏或华氏单位C/F的指示可以很容易地从功能按钮选择。

典型应用

密闭输送,库存,储罐,管道,驳船,船舶,铁路槽, 油罐车(推荐操作:API7,油轮和油码头安全指南)

其他应用:检验系统API4

物质材料:所有石化产品,腐蚀性,耐酸、碱,粉末。糖蜜,糖浆,蒸馏酒。

PETROLEUMGAUGING THERMOMETER

The TP9 employs the proven RTD design that has been used in the TP7 andTP8 for many years. A sealed industrial quality overlay provides a userinterface that is easy to use with gloves. A stainless steel enclosure protectsthe circuit board and large LCD from penetration by impact, water and reactiveliquids.

The new TP9 circuitboard is an evolutionary step up from our highly accurate, reliable andsuccessful TL1 laboratory thermometer. The Power Button’sprimary function powers the instrument for intervals of about 20 minutes sincethe last button was accessed. The Power Button can also be used to conservepower and clear the memory, or to make adjustment while in calibration mode. Asimple menu operation is displayed by holding the Function Button, andalternately functions to allow adjustments in the calibration mode. Arrows onthe left side of the display show the direction of the temperature reading andwhether stability has been reached. At the user’s discretion stabilized temperaturescan be logged at numerous liquid levels for a running average and laterdisplayed for the user’s documenting purposes. But thisfeature never interferes with simply getting an accurate temperature reading.

To endure the environment and beintrinsically safe, the TP 9 is manufactured of materials, which are bothimmune to petrochemicals and are non-sparking. The enclosure is made ofstainless steel. The probe assembly is constructed using non-stick cable andstainless steel sensor components.

SPECIFICATIONS

Maximum Dimensions: 10”L x 4.25”H x 6.4” W

Probe: 304 StainlessSteel, Sealant, Aramid Fiber Reinforced, FEP or PFA Cable Jacket, CoaxialConstruction

Enclosure Material: Stainless Steel Acetal (Delrin) Probe Holder PolyvinylchlorideFaceplate

Batteries: 2 AA Alkaline; BatteryLife of approximately 200 hours Battery manufacturer’s battery operating temperatature range -4 to130°F, -20 to 54°C

Note: Battery may not provide adequate power ifambient temperature is extremely low or high.

Temperature: Resolution 0.01

Range: -40 to +400°F

-40 to +204°C

Calibrated Accuracy:

±0.2°F from 32 to 200°F ±0.5°F from 200 to 400°F

±0.1°C from 0 to 100°C ±0.3°C from 100 to 200°C 4 Point NIST Traceable Report of Test

Long-term drift not to exceed 0.05%/year

Meets API requirements

OPERATIonAL ATTRIBUTES

Easily replaceable AA Batteries, provides an estimated *200hours

operation.

Circuit logic automatically indicates lowbattery condition, automatically shuts off after twenty minutes, showstemperature trend and stabilization, displays error codes for failuredetermination.

The low power backlight for night operation isphoto sensor controlled for convenience and battery conservation.

In nighttime conditions the backlightilluminates the display.

Celsius or Fahrenheit units with C/F indicationcan be easily selected from the Function Button.

User Manual explains intuitive calibrationprocedure that can be done through the external faceplate buttons.

TYPICALAPPLICATIONS

CustodyTransfers, Inventory, Tank, Pipeline, Barge, Ship, Railcar, Tank Truck.(Recommended Operation: API 7, Intl. Safety Guide For Oil Tankers andTerminals.)

Other Applications: Proving Systems (API 4)

Materials: All petrochemicals, caustic, acid, alkalies,powders. Molasses, syrups, distilled spirits.