| 产地 | 其他(自填) |

|---|---|

| 风格 | 其他 |

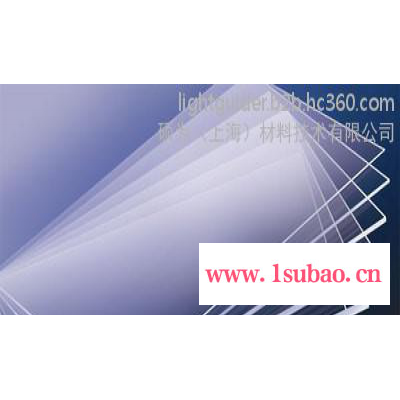

| 厚度 | 0.1mm |

| 加工工艺 | 热滚印 |

| 类型 | 超薄 |

| 透光率 | 大于95% |

| 外形尺寸 | 可弯曲 |

| 显示模式 | 反射式 |

| 重量 | 0.01 |

| 主体材质 | 亚克力,其他 |

| 光源形状 | 点状 |

| 品牌 | RLO |

| 加工定制 | 是 |

| 灯光颜色 | 橙色,冷白,黄色,绿色,蓝色,红色,正白,暖白 |

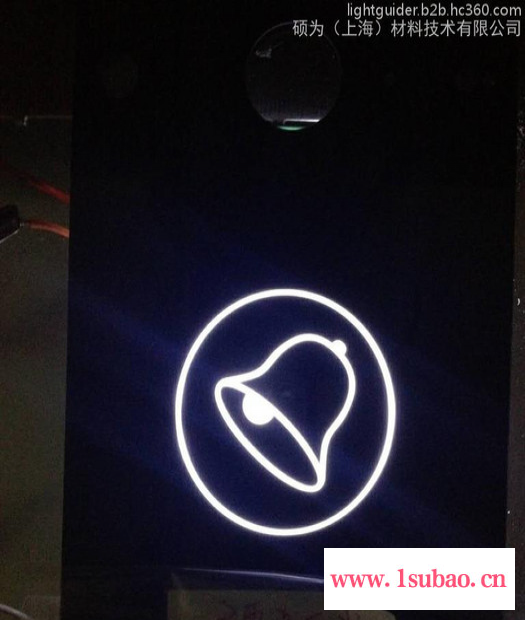

●產品為目前業界**輕**薄,極致薄度0.1mm。

Lighter and thinner designer for customers with 0.1 millimetersthickness in its slimmest dimension.

●單軸曲面,更豐富的ID設計應用。

Flex LGF (x with flex PCB) make productdesign easier

●材質耐衝擊性高,協助客戶通過落下測試。Material with high anti-impact is easier topass the drop test of customer`s products

●突破製程限制,克服以往因材質劣化造成的邊緣黃化問題Without Non-yellowing issue likeinjection process

●改良材質降低短波長光線吸收率,導光後不會在出光邊產生黃化。LGF of material is low short-wavelength absorption rate makes uniform Chromaticity

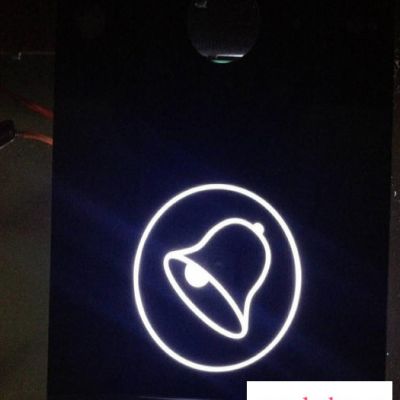

●精細的導光結構,微結構直徑尺寸僅30-40um,顯示或發光區塊更均勻綿密。人眼舒適度高。

Micro-structure is under 30~40um make LGF uniform and make user feelcomfortable

●亂數化佈點設計,不與其他光學膜片或結構層產生干涉影響。

Special micro-structure design can match all existing Prism or opticalstructure

●綠色產品,微結構製程屬物理變化不使用溶劑、樹脂等生成光學結構物。

Hot embossing is a physical processwithout chemical solvent and resin makes really green products.

●取代射出模具品,開發週期短開發費用低、且具更大產出效能。一套熱壓開發=8台射出機+8套塑膠射出模具。Hot embossing with high speed development ,low mold feeand great capacity.1 set embossing tooling =8 set Injection molding machine +8 set Injection mold